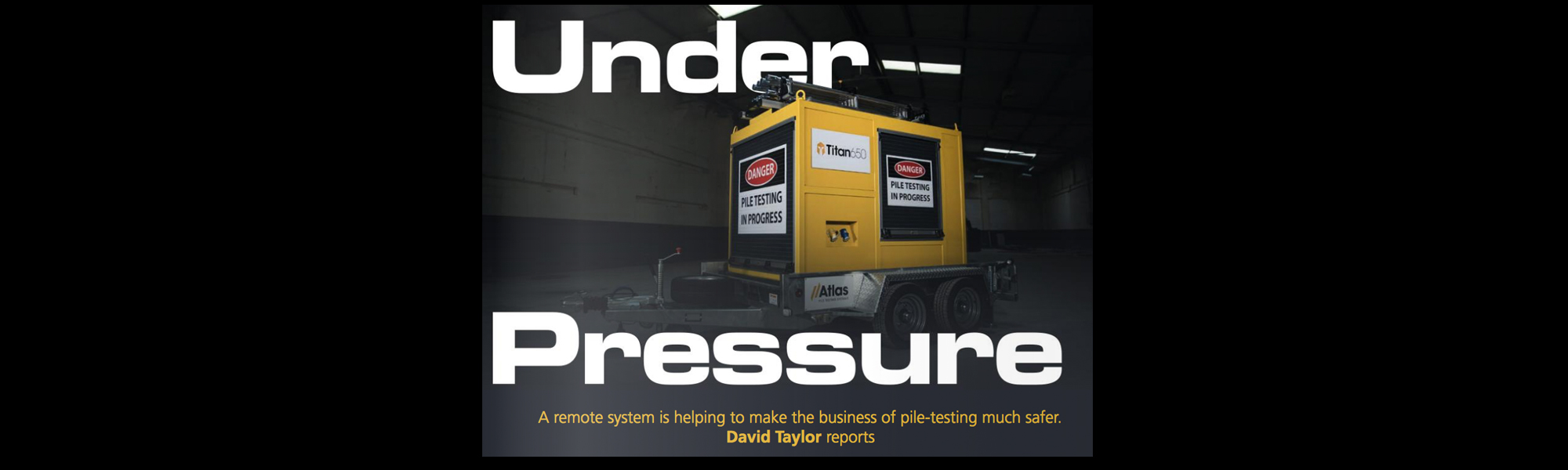

Construction Index Report On Benefits Titan 650 Brings To Pile Testing Industry

The Construction Index magazine has reported on the safety benefits of the Titan 650 to the pile testing industry.

They examine the dangers still faced by the industry and the ‘outdated’ techniques and technologies used despite incredible advances elsewhere in the construction index in the October issue of the magazine.

The Construction Index is a monthly magazine for contractors, plant hirers and other companies in the construction supply chain with a circulation of more than 40,000 readers.

Editor David Taylor, a respected construction industry journalist with more than 25-years experience, writes in the October issue how the pile testing industry ‘largely lives in the past.’

He claims there is ‘still too high a risk of accidents as ‘people continue to work too closely to high pressure hydraulics’ despite the advancement of testing procedures in the UK.

He writes: “It is 20 years since the Institution of Civil Engineers launched the Specification for Piling and Embedded Retaining Walls (SPERWall) and for clients, engineers and contractors, it remains the leading authority on piling and retaining walls in the UK and Europe.

“The industry demands increasing standards of accuracy and transparency, and higher levels of safety – all of which the Atlas Pile Testing Systems appears to be able to satisfy.

“Clearly much has changed since the publication of the first edition in 1996 and technological innovations have allowed the construction industry in general to make huge advances.

“Wireless and Bluetooth technology, remotely controllable heavy plant, 3D modeling, asset mapping, cloud computing and predictive software have transformed the industry.

“The Third Edition of SPERWall, published earlier this year in response to developments in piling techniques and changes to European standards, is designed to set new standards for safety and accuracy.

“Yet for some reason, the piling industry largely lives in the past, relying on outdated technology that was used long before the ICE drafted that first edition of SPERWall.”

Taylor believes, even though testing procedures in the UK have advanced, the dangers to operatives remains too high.

He adds: “There is still too high a risk of accidents as people continue to work too close to high pressure hydraulics exerting thousands of tonnes of load. This should be avoided if at all possible as any fault, error or failure in the system could result in serious injury.”

“Harnessing the technology used in other departments of the Datum Group, O’Rourke’s engineers spent two years developing and trialing a new, fully automated and unmanned static load testing system, the Titan 650.’

Taylor highlights this risk, or rather the desire to remove such dangers, as the inspiration behind Rory O’Rourke, CEO of the Datum Group and founder of Atlas Pile Testing Systems, drive to develop the Titan 650.

“There are still too many stories of operatives being injured or even killed when involved in pile testing,” O’Rourke told Construction Index, “and I simply would not allow my staff to be placed in harm’s way, so we decided to do something about it.”

O’Rourke launched the Titan 650 earlier this summer and Nottingham based specialists Non Destructive Testing Services have already purchased and started working with the Titan 650.

Atlas Pile Testing Systems have a number of orders for the Titan and are conducting demonstrations on a weekly basis to interested parties.

* Read the full article in the Construction Index below or click this link to read the e-magazine online.

* To learn more about the Titan 650 or to book a demonstration contact Atlas Pile Testing systems by clicking this link or by emailing: info@atlaspiletesting.com